According to a report by the United Nations Food and Agriculture Organization, approximately one-third of global soils are degraded, resulting in diminished soil fertility and reduced nutritional quality of grains, fruits, and vegetables. This is particularly critical in the Middle East and North Africa, two of the world's regions with the most barren arable land. Under extreme climatic conditions, issues like soil degradation and scarcity of freshwater resources pose significant challenges to local crop production.

How can we achieve the cultivation of more abundant and higher quality crops with minimal or no use of arable land and reduced water consumption?

At the 15th China (Dubai) Trade Fair, GMY invites you to explore new methods of agricultural cultivation and production!

LumiAgro Plant Factory Solution - Changing Food Production with the Power of Technology

As an advanced stage of modern facility agriculture, the plant factory is a system that integrates high technology and advanced equipment. It combines biotechnology, engineering technology, and system management, enabling agricultural production to break free from natural ecological constraints and achieve planned, year-round factory cultivation.

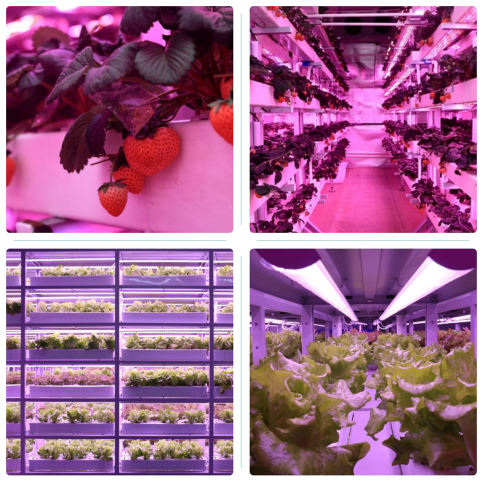

Strawberries and Vegetables Cultivated in the LumiAgro Plant Factory

Plant factories represent a dynamic and promising field in the industrialization of agriculture, fully leveraging advanced technological achievements, and signify the future direction of agricultural development. Thus, at the upcoming 15th China (Dubai) Trade Fair, GMY will introduce innovative "Plant Factory Solutions" to the Middle East and North Africa region, offering a more environmentally friendly and efficient option for modern facility agricultural planting in areas with extreme climates.

High Precision Environmental Control: Enhancing Yield and Quality of Fruits and Vegetables

LumiAgro, a GMY brand focused on research, development, and innovation in the field of lighting and plant growth, has accumulated nearly eight years of experience in planting and lighting R&D and manufacturing. As the core of R&D, the LumiAgro Plant Factory provides scientific data and practical validation support for agricultural planting lighting and overall solution management.

LumiAgro Plant Factory

In the LumiAgro Plant Factory, high-precision environmental control effectively manages factors such as temperature, humidity, lighting, CO₂concentration, and nutrient solutions for the growth and development of plants. This management minimizes the impact of natural conditions and pests, enabling efficient year-round production of vegetables and fruits, and ensuring stable yields.

Moreover, after years of experimental research, the LumiAgro Plant Factory has successfully cultivated a variety of vegetables, fruits, and herbs, including Italian lettuce, red maple lettuce, sesame leaf, basil, cherry radish, and pansy. These vegetables and fruits, favored for their excellent taste and higher nutritional value, have become premium ingredients for high-end hotels and customers concerned about food quality.

Vertical Multilayer Cultivation: Saving and Expanding Cultivable Space

The LumiAgro Plant Factory's diverse application scenarios include ensuring daily vegetable supply in densely populated cities and self-sufficiency in special situations like city traffic closures. In harsh environments such as tropical deserts, border outposts, and island survival, plant factories play a crucial role, offering clear advantages in ensuring stable, local food supply, expanding cultivable space, and protecting arable land.

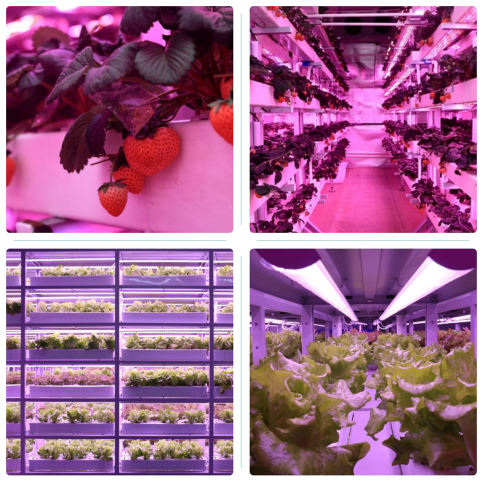

The LumiAgro Plant Factory, with its multilayer vertical cultivation technology, effectively saves space. Covering about 1200 square meters with a 6 to 10-layer vertical system, the total cultivation area reaches approximately 6000 square meters, yielding about 270,000 kg annually. This design significantly enhances productivity per unit area, especially important for areas with limited land availability.

Diagram of Multilayer Vertical Cultivation in the LumiAgro Plant Factory

Scientific Hydroponic Cultivation Technology: Safer Food with Water Conservation and Environmental Protection

In the LumiAgro Plant Factory, fruits and vegetables are grown on foam board seedbeds, absorbing nutrient solutions in an indoor environment. This hydroponic cultivation technology avoids common soil cultivation issues like pests, diseases, and heavy metal contamination. Importantly, it reduces the use of pesticides and insecticides, significantly improving food safety and achieving "zero pollution, zero agricultural residues, zero hormones," ensuring the purity and health of produce.

Additionally, the LumiAgro Plant Factory uses a closed-loop hydroponic irrigation system, reducing water usage by over 90% compared to traditional agricultural irrigation, helping to lower water consumption in agricultural production.

GMY Warmly Invites You to Join the Grand Event

The plant factory is a crucial element of modern agricultural industrialization, with the development of more flexible, sophisticated, multifunctional, and multi-scenario plant factories being key to efficient and sustainable agricultural technology development. At the upcoming 15th China (Dubai) Trade Fair (Booth No. AI209-AI210), GMY looks forward to your visit to discuss a greener and more efficient agricultural future.

How can we achieve the cultivation of more abundant and higher quality crops with minimal or no use of arable land and reduced water consumption?

At the 15th China (Dubai) Trade Fair, GMY invites you to explore new methods of agricultural cultivation and production!

LumiAgro Plant Factory Solution - Changing Food Production with the Power of Technology

As an advanced stage of modern facility agriculture, the plant factory is a system that integrates high technology and advanced equipment. It combines biotechnology, engineering technology, and system management, enabling agricultural production to break free from natural ecological constraints and achieve planned, year-round factory cultivation.

Strawberries and Vegetables Cultivated in the LumiAgro Plant Factory

Plant factories represent a dynamic and promising field in the industrialization of agriculture, fully leveraging advanced technological achievements, and signify the future direction of agricultural development. Thus, at the upcoming 15th China (Dubai) Trade Fair, GMY will introduce innovative "Plant Factory Solutions" to the Middle East and North Africa region, offering a more environmentally friendly and efficient option for modern facility agricultural planting in areas with extreme climates.

High Precision Environmental Control: Enhancing Yield and Quality of Fruits and Vegetables

LumiAgro, a GMY brand focused on research, development, and innovation in the field of lighting and plant growth, has accumulated nearly eight years of experience in planting and lighting R&D and manufacturing. As the core of R&D, the LumiAgro Plant Factory provides scientific data and practical validation support for agricultural planting lighting and overall solution management.

LumiAgro Plant Factory

In the LumiAgro Plant Factory, high-precision environmental control effectively manages factors such as temperature, humidity, lighting, CO₂concentration, and nutrient solutions for the growth and development of plants. This management minimizes the impact of natural conditions and pests, enabling efficient year-round production of vegetables and fruits, and ensuring stable yields.

Moreover, after years of experimental research, the LumiAgro Plant Factory has successfully cultivated a variety of vegetables, fruits, and herbs, including Italian lettuce, red maple lettuce, sesame leaf, basil, cherry radish, and pansy. These vegetables and fruits, favored for their excellent taste and higher nutritional value, have become premium ingredients for high-end hotels and customers concerned about food quality.

Vertical Multilayer Cultivation: Saving and Expanding Cultivable Space

The LumiAgro Plant Factory's diverse application scenarios include ensuring daily vegetable supply in densely populated cities and self-sufficiency in special situations like city traffic closures. In harsh environments such as tropical deserts, border outposts, and island survival, plant factories play a crucial role, offering clear advantages in ensuring stable, local food supply, expanding cultivable space, and protecting arable land.

The LumiAgro Plant Factory, with its multilayer vertical cultivation technology, effectively saves space. Covering about 1200 square meters with a 6 to 10-layer vertical system, the total cultivation area reaches approximately 6000 square meters, yielding about 270,000 kg annually. This design significantly enhances productivity per unit area, especially important for areas with limited land availability.

Diagram of Multilayer Vertical Cultivation in the LumiAgro Plant Factory

Scientific Hydroponic Cultivation Technology: Safer Food with Water Conservation and Environmental Protection

In the LumiAgro Plant Factory, fruits and vegetables are grown on foam board seedbeds, absorbing nutrient solutions in an indoor environment. This hydroponic cultivation technology avoids common soil cultivation issues like pests, diseases, and heavy metal contamination. Importantly, it reduces the use of pesticides and insecticides, significantly improving food safety and achieving "zero pollution, zero agricultural residues, zero hormones," ensuring the purity and health of produce.

Additionally, the LumiAgro Plant Factory uses a closed-loop hydroponic irrigation system, reducing water usage by over 90% compared to traditional agricultural irrigation, helping to lower water consumption in agricultural production.

GMY Warmly Invites You to Join the Grand Event

The plant factory is a crucial element of modern agricultural industrialization, with the development of more flexible, sophisticated, multifunctional, and multi-scenario plant factories being key to efficient and sustainable agricultural technology development. At the upcoming 15th China (Dubai) Trade Fair (Booth No. AI209-AI210), GMY looks forward to your visit to discuss a greener and more efficient agricultural future.

Comments

Post a Comment